The Importance Of Material Handling Systems — Brought to You By Your Colorado Manufacturer

Posted on April 2nd 2023

Learn More

Karl W. Schmidt Mfg inc. is certified by FedEx to supply welded power conveyors.

Posted on April 1st 2023

Learn More

The Karl Schmidt Mfg Inc. Guarantee — Extending Far Beyond Your Purchase

Posted on March 28th 2023

Learn More

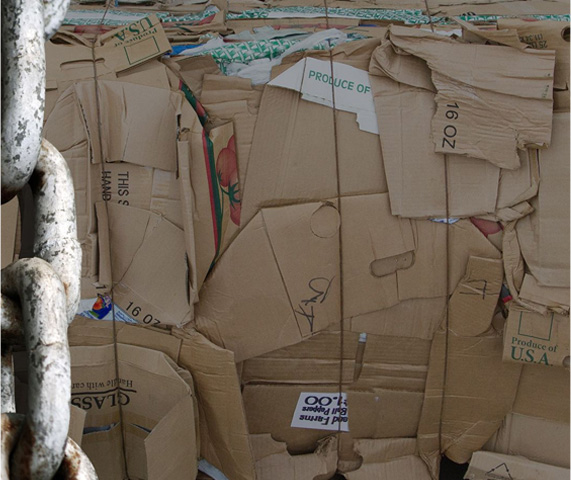

The Role of Our Material Handling Systems in the Circular Economy of Recycling

Posted on March 25th 2023

Learn More

Industrial Conveyor Systems — Why Choose Karl Schmidt Mfg. Inc.?

Posted on March 24th 2023

Learn More