Find Replacements for Your Recycling Solution

Sometimes, the belt on your conveyor might break or need to be replaced. That’s why Karl Schmidt Mfg offers replacements belts! If you don’t see the replacement belt you need listed below, just contact the team at Karl Schmidt Mfg and we’ll help you find the replacement you need!

Karl Schmidt Mfg has a wide selection of replacement belts available, including:

- 3 Ply Roller Chain Conveyor Belts

- 2 Ply Roller Chain Conveyor Belts

- 3 Ply Rubber Conveyor Belts

- PVC 350 Conveyor Belts

- PVC 250 Conveyor Belts

Replacement Conveyor Belts

Replacement Steel Conveyor Belts

Karl Schmidt Mfg. offers 2 types of replacement steel conveyor belts. Lead time, depending on our schedule is typically 4-8 weeks. Value added benefits of a steel belt purchased from our company include: experience, competitive prices, on-time and quality ensured.

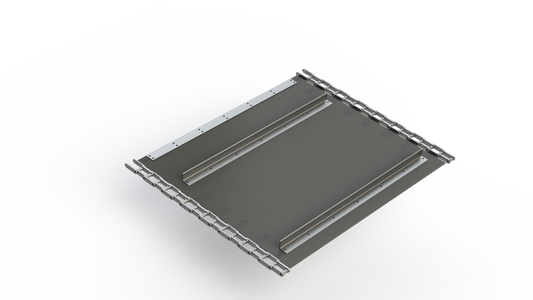

Apron Style Replacement Conveyor Belts

This belt is similar to a hinge steel belt, but instead of hinges it has steel formed pans (¼”, 3/8”, ½”) that overlap one another to help seal the bottom so material remains on the top surface. ¼”, 3/8”, ½”side wings on the side that help ensure material remains on the belt body.

Hinged Steel Replacement Conveyor Belts

This belt has ¼” hinges spread throughout the body of the belt which allow the belt to flex around the conveyor frame. ¼” side wings on the side that help ensure material remains on the belt body. This belting is a heavy duty belt compared to rubber and PVC which will last longer, but costs about 15-20% more.

Replacement Chain Belt Conveyor Belts

Karl Schmidt Mfg. offers 6 types of replacement chain belt conveyor belts. Lead time, depending on our schedule is typically 4-8 weeks. Value added benefits of a steel belt purchased from our company include: experience, competitive prices, on-time and quality ensured. If your application requires product specifications not listed below, contact us and we would be glad to help.

3 Ply Roller Chain Conveyor Belts

Rubber 3 Ply (3 layers of synthetic materials and 4 layers of rubber that has a 330 PIW (pounds per inch width)) or 350 PVC (woven plastic with a 350 PIW) belting that is fastened between two chains, which are located on both sides of the belting. The side wings, which are typically ¼” thick by 4” tall, keep the material on the body of the belt. There are cleats spaced every 2ft – 4ft apart that hold the chains and the belting together as well as move materials up inclined frames. Roller chains typically have 3” or 4” flanged hardened wheels/rollers that track the belting and increase longevity.

2 Ply Roller Chain Conveyor Belts

Rubber 2 Ply (2 layers of synthetic materials and 3 layers of rubber that has a 220 PIW (pounds per inch width)) or 250 PVC (woven plastic with a 250 PIW) belting that is fastened between two chains, which are located on both sides of the belting. The side wings, which are typically ¼” thick by 4” tall, keep the material on the body of the belt. There are cleats spaced every 2ft – 4ft apart that hold the chains and the belting together as well as move materials up inclined frames. Roller chains typically have 3” or 4” flanged hardened wheels/rollers that track the belting and increase longevity.

Replacement Rubber Conveyor Belts

Karl Schmidt Mfg. offers a variety of replacement rubber conveyor belting. We offer quick deliveries, cut to length, and completive market prices. Typical lead time, depending on the application, is 1-2 weeks delivery. A few key elements of rubber belting are the light weight, cost effective and durable.

3 Ply Rubber Conveyor Belts

Rubber 3 Ply (3 layers of synthetic materials and 4 layers of rubber that has a 330 PIW (pounds per inch width)). The belt splice/lacing is a metal hinge that is sized according to the belt width/thickness. There are cleat options available if there is an incline. This belting is typically used on slider bed conveyors.

Replacement PVC Conveyor Belts

Karl Schmidt Mfg. offers a wide variety of PVC conveyor belting. Offering quick deliveries on cut lengths at pricing that are competitive to the market. A large value proposition of PVC belting is the versatility of the belting. A few key features include friction surface, bare, and flame resistant backs are optional on either side of the belting. Fast lead times of 1-2 weeks depending on the customer.

PVC 350 Conveyor Belts

Woven plastic that has a 350 PIW.

PVC 250 Conveyor Belts

Woven plastic that has a 250 PIW.

Other Belting Replacement/Repair Parts

Karl Schmidt Mfg. offers a wide variety of replacement belting parts. If you are not looking for a complete replacement belt, we offer solutions to get you up and running.

Conveyor Belt Repair Kits

We offer replacement kits to patch torn or damaged belting. Lead times for replacement kits are typically 1 week.

About Us

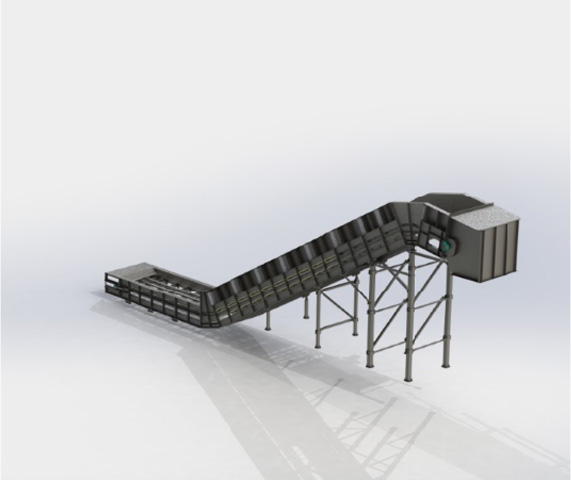

For over 40 years Karl Schmidt’s Conveyor’s have provided the recycling industry with top-tier heavy duty conveyors via design, manufacturing and customer service. Now, Karl Schmidt Manufacturing continues the KWS legacy and we pride ourselves in doing what is always right for the customer. One of the most important aspects of having a thriving business is service.

Applications

Regardless if it’s a single slider bed conveyor, a small engineering services project, or a single stream MRF, the Karl Schmidt Mfg.’ outlook remains the same, “Do What is Right For the Customer” regardless of their purchase!

Products

We have been engineering & manufacturing conveyors and related recycling equipment since 1978. We have installed thousands of Conveyors, a variety of dual stream systems and single stream recycling systems all over the United States as well as internationally around the World.